Blister Design, Packaging, Accessories

Design is the first stage in the ``life cycle`` of each package.

It gives the possibility of creating its unique appearance or functionality

We encourage you to use your imagination and create unique packaging 😊

We will take care of the implementation of these projects!

We provide consulting, design and production of necessary equipment

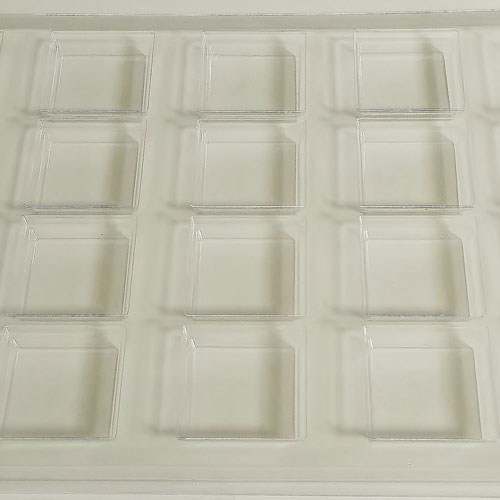

Molded parts

Intended for sealing with blister cartons or for assembling a blister using the push-in method.

Thermoformed packaging

Self-contained, made entirely of foil, double-sided thermoformed packaging closed with snaps, protrusions or permanently welded around.

Folding boxes

Folding boxes die-cut from a die.

Trays and inserts

Various types of trays (transport, display), inserts, dividers.

Equipment necessary for various types of production

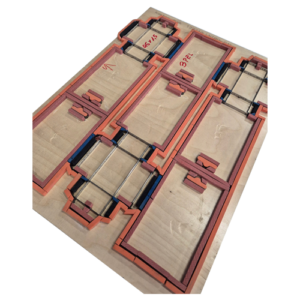

Bookbinding cutting die

Finishing

Gilding and embossing dies (hot stamping)

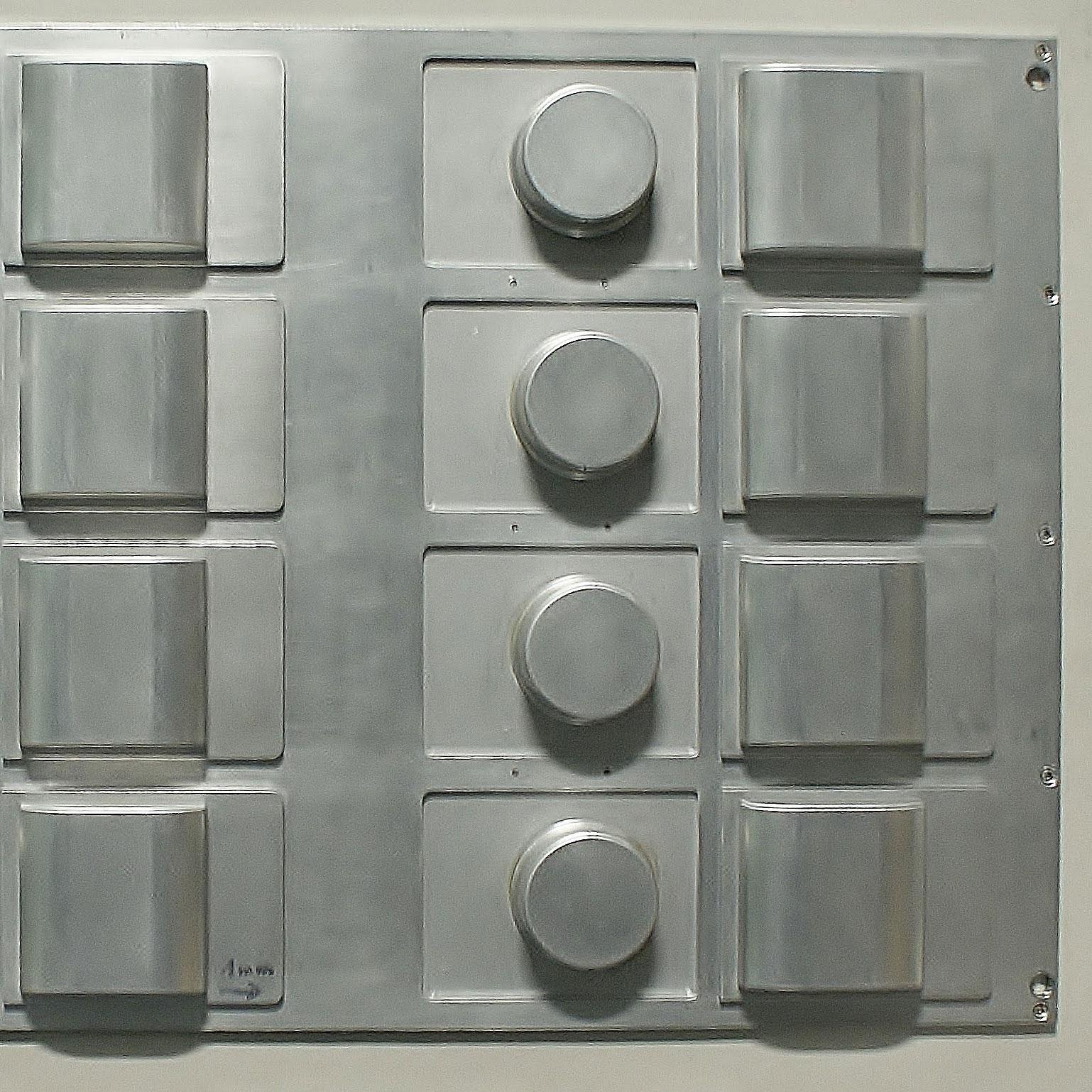

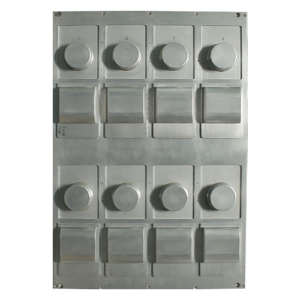

Thermoforming

Mould (aluminum or resin)

Welding

Welding template